Add to Cart

What is 309S stainless steel?

Alloy 309 (UNS S30900) is an austenitic stainless steel developed for use in high temperature corrosion

resistance applications. The alloy resists oxidation up to 1900°F (1038°C) under non-cyclic conditions.

Frequent thermal cycling reduces oxidation resistance to approximately 1850°F (1010°C).

What is mirror finish stainless steel?

On stainless steel, a mirror finish is a highly-polished commercial finish characterised by a bright, shiny

and reflective surface. You'll most commonly find it in aesthetic pieces, such as public architecture, tapes

and furniture.

What is in stainless steel?

Like all other kinds of steel, stainless steel is made primarily from iron and carbon in a two-step process.

What makes stainless steel different is the addition of chromium (Cr) and other alloying elements such as

nickel (Ni) to create a corrosion-resistant product.

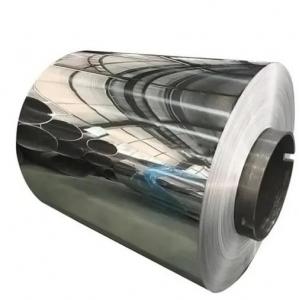

Product description

| Item Name | Stainless Steel Coil/Strip Customize |

| Material Grade | 201,301,302,303,304,304L,316,316L,321,308,308L,309,309L,309S,309H, 310,310S ,410,430,2205,409 etc |

| Size | customized Special specifications can also be produced according to drawing and sample |

| Surface Treatment | No.1, 2b Mill Finish, Ba Bright Annealed, #4 Finish,Mirror Finish |

| Length | As per requirement |

| Color | Silver, or color coated |

| Quality | Top |

| Certification | ISO9001 |

| Application | wire-drawing, weaving of wire mesh, soft pipe, bean of cabinet, steel wire,etc. |

| Packing | Exportsea worthy packing with each bundle tied and protected, Or as to clients' requirements. |

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q1: Are you a factory or trading company?

A1: We are a Chinese manufacture of steel pipes with both factories and trading companies.

Q2.How can you ensure the quality of your product?

A2.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q3.What is your delivery time and the supply ability?

A3.The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

Q4.What kind of equipment in your factory?

A4.Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll,advanced processing and testing equipment,which makes our product better quality with efficiency.

Q5.About the complaint,quality problem,etc aftersales service,how do you handle it?

A5.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.